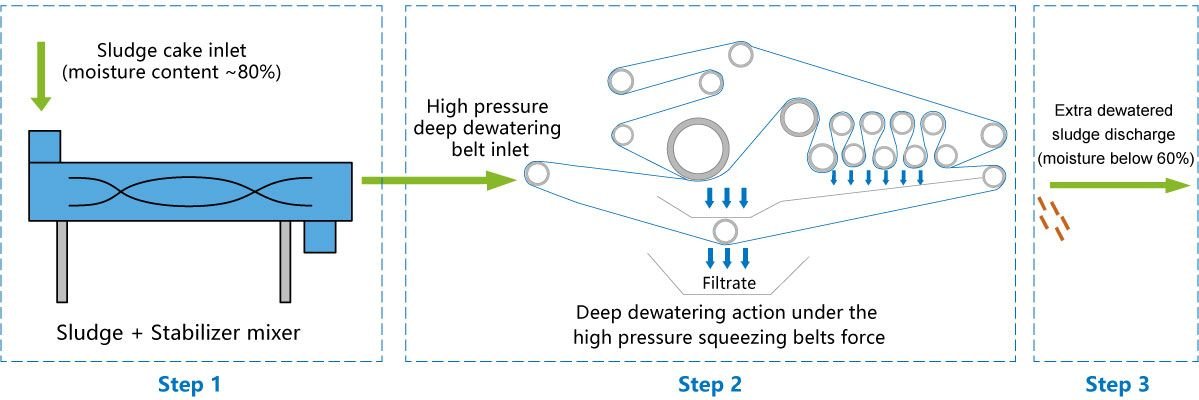

The high pressure belt BNSD, continuous sludge deep dewatering technology, treats sludge cake (with average moisture content of 80%), with the addition of sludge stabilizer. After deep dewatering, the sludge moisture is reduced to below 60%, to meet landfill standards of sludge disposal. Also it can be used as extra treatment for drying, incineration, bricks making, cement kiln processing, or other treatment technologies to improve the overall dewatering process in an economic way.

The sludge cake, with ~80% moisture, is mixed with sludge stabilizer to reach a uniform texture.

Under the high efficiency mixer effect, the bonds between the sludge particles is destroyed, increasing the porosity, and then discharged in form ofgranules, to improve the deep dewatering effect.

The granulated sludge enters the continuous sludge deep dewatering machine, to achieve the extra dewatering effect under the high pressure & the intensive force of the double belts.

According to the theory of filtration and squeezing, the thinner the sludge cake, the larger of the cake pores, the smaller moisture resistance, the better pressing & filtering effects. The secondary dewatered sludge cake is shaped like ~10mm flakes size, with moisture content below 60%, easy to crush and to dry.

The discharged cake moisture is greatly reduced, and ready for final disposal.

35 Adelaide Road, Dannevirke 4978 New Zealand

Copyright © 2024 Enviroden., Ltd. All Rights Reserved.