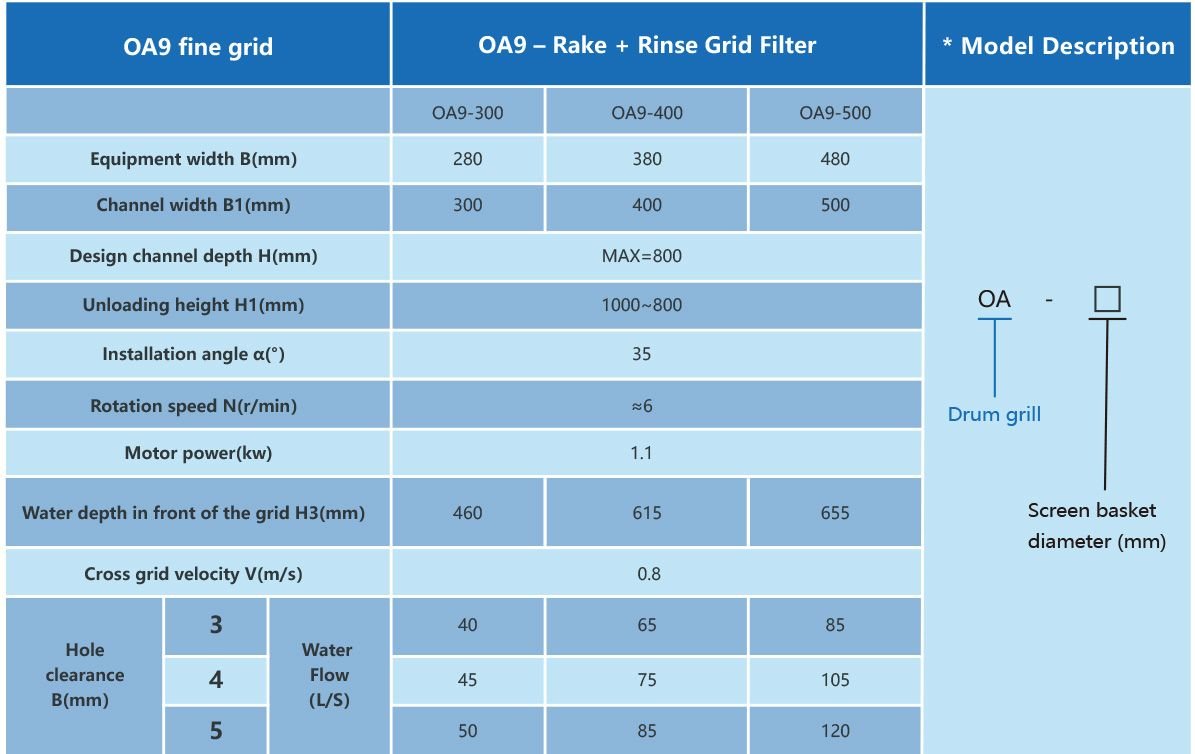

Filter gap 3~5 mm

For small and medium flow sewage filtration

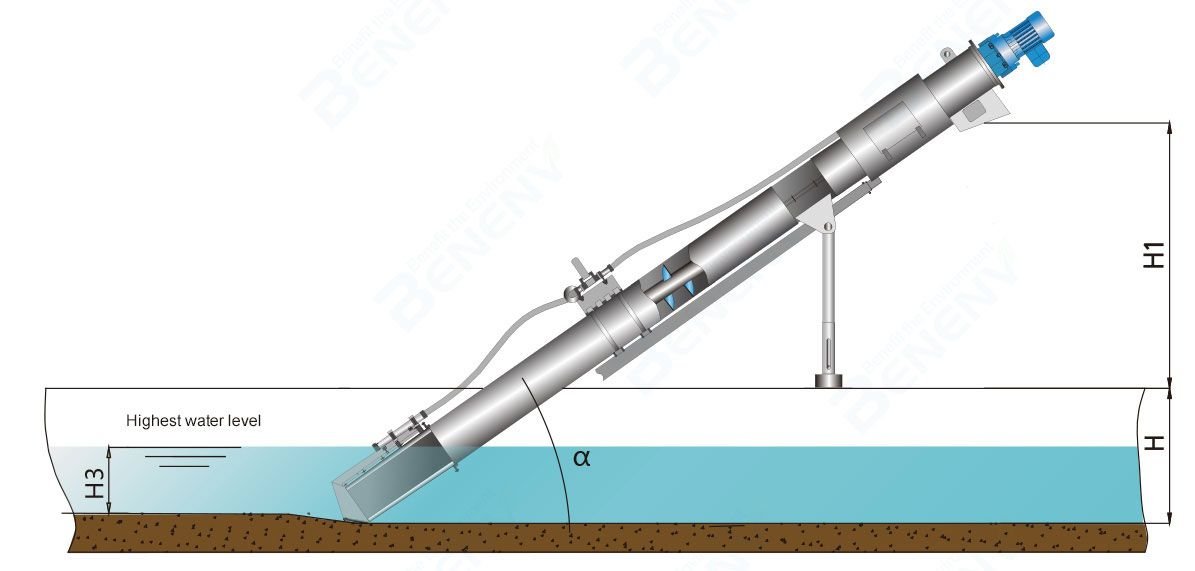

The equipment is installed at an angle of 35°. Sewage flows into the sieve from the opening of the end face of the grille. Scum, sediment and suspended solids will be intercepted by the screen .The waste on the grid is lifted up through the closed screw elevator, dewatered, pressed and transferred to the discharge opening over the bin.

The OA9 series grille works in a unique way, which can concentrate the filtering, washing, transportation, pressing and dewatering functions in one device. Depending on the selected screen pitch / pore size and mechanical specifications (screen basket diameters up to 700 mm), it can be adapted to various applications and processing flows. The machine can be installed in the box.Can also be installed directly in the water channel.

35 Adelaide Road, Dannevirke 4978 New Zealand

Copyright © 2024 Enviroden., Ltd. All Rights Reserved.